I’m currently undertaking a year long Icon Internship in Preventive Conservation with the National Trust for Scotland. An important part of my role as a preventive conservator is to ensure that the collections in my care are stored and exhibited appropriate environmental conditions. I’ve completed environmental monitoring as part of the internship and in previous roles; however, I hadn’t had an opportunity to undertake the important task of calibrating the environmental equipment to ensure their accuracy and functionality. The calibration process offered an ideal opportunity to get hands on with the equipment!

The adage of giving a ‘spring clean’ to a house doesn’t necessarily apply to historic interiors, where an annual deep clean typically occurs over the winter months. Instead, spring is the time for environmental logger calibrations for the National Trust for Scotland! The Trust use Hanwell ML4000 loggers in their properties across Scotland. The first step to the calibration process was to gather all the loggers requiring calibration into one location – this necessitated delivery of loggers from across Scotland, arrivals by post, and some site visits for collection (Image 1).

Logger in storage

Prior to undertaking the logger calibrations, all the recorded data from the previous year needed to be downloaded and saved into a central location. The data provided by the loggers is continuous with each year adding to the current file. This means that one file can provide environmental data from each logger for years and can be searched and viewed by date for reporting and analysis. The downloaded data is then analysed to determine if environmental conditions met NTS parameters for the previous year and to note any changes compared to the last reported data. This provided me with an opportunity to review data for a selection of properties and write their annual reports noting changes in condition. In reviewing the data over previous years I could clearly see how seasonal trends in different locations are apparent, for instance higher humidity levels in coastal properties!

Setting up the loggers for calibration

We worked in a designated meeting room over two days to complete the calibration process (Image 2). The room is sealed with glass doors and thermostat controlled which was essential as we needed to specify the room temperature required for our calibrations. A salt solution of magnesium nitrate was used which provides 54% relative humidity at 20°C. The salt solution is housed in a canister that produces a vapour in its drum where the environmental logger sensor is attached. The loggers are then left for one hour to acclimatise to the salt vapour (Image 3).

Loggers with salt canisters attached

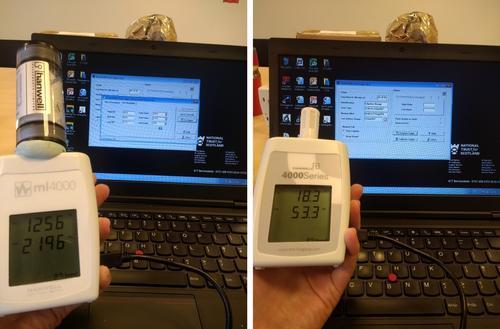

The data loggers are set to calibration mode to enable the RH values to be read and recorded (Image 4). These numbers are used to adjust the settings of the loggers in the Hanwell Log32 software. After an hour attached to the salt canister the data point numbers are recorded again and the difference to the middle point (54% RH) is calculated. For example, if the sensor read 1140 before the calibration and reads 1175 after calibration then an adjustment needs to be made of +35 on each of the three data points. If a sensor is more than 5% off from the middle point RH then a full 3-point calibration may be needed to ensure accuracy. Once the data points are adjusted the logger is then set to display mode and the calibration is complete (image 5).

(Left): Logger in calibration mode

(Right): Logger in display mode

The calibration process is also an opportunity to check the sensors for any technical faults and change batteries. A few sensors had errors with their display screens, ran out of battery power, or couldn’t be set to calibration mode. These technical faults required further investigation and for some a call to Hanwell for technical support. After making additional adjustments and working in secondary software all errors were resolved and we could carry on with the calibration process.

Overall, I thoroughly enjoyed getting hands on with the environmental loggers and the salt canisters! I was able to gain valuable skills in how to undertake a large scale calibration of environmental equipment including trouble shooting problems with the software and equipment. It was interesting to see how the process works and how the values are calculated and recorded on the environmental software. It also really emphasised the importance of maintaining the accuracy of the loggers to ensure environmental conditions are appropriate and to enable any issues within a building or with heating or humidistats to be identified and remedied as early as possible. I feel this is a key area for developing my skills as a preventive conservator and during my internship at the Trust!